Injection Molder

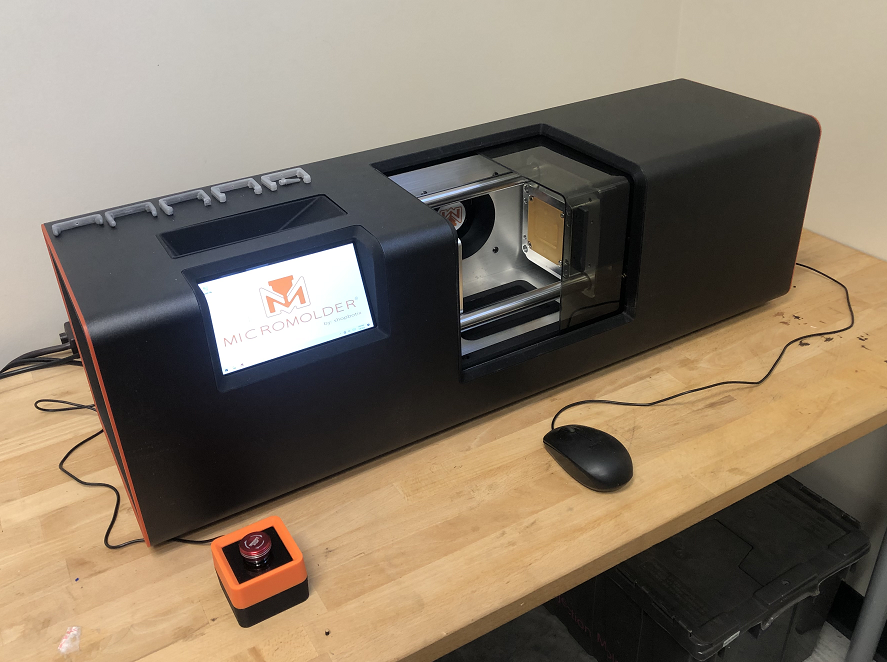

The injection molder is used to make multiple small plastic parts using a mold. In the Maker Lab, we have a MicroMolder Evo and an LNS Technologies Model 150A injection molder.

Quick Reference

Training Required: Basic Training and Injection Molder Training

MicroMolder Evo Workspace: Mold cavity maximum size 1.85 cubic inches (3D printed tooling), 1.35 cubic inches (aluminum tooling)

Model 150A Workspace: Mold cavity maximum size is 1.25 cubic inches

Materials: Plastics- Polyethylene (PE), Polypropylene (PP), and Thermoplastic elastomer (TPE)

Material Fees: We have limited plastic pellets available for use in the Maker Store or you can provide your own. We also have tooling for 3D printed molds for both injection molders or you can provide aluminum molds.

Common Terminology: Sprue- the channel used to inject the plastic into the mold. This creates waste material that is removed from the part once injected.

PDF Links

Instructables Guide to Plastic Injection with Epoxy Mold

Instructables Guide to Plastic Injection with Aluminum Epoxy Mold

Video Links

Manufacture Information

LNS Technologies Techkits Website

Sample Projects

|

Replica of 3D printed part Made an epoxy form for injecting into to replicate a 3D printed chess pawn. |

|